Tshuab dhos

-

CH61200L CNC tig chaw nrog C axis

Lub tshuab no yog mated nrog C axis, pub X thiab Z axis, peb axis tuaj yeem txuas thiab txav mus ua ke nrog ntau txoj haujlwm thiab kev ua haujlwm siab.

-

Plaub phau ntawv qhia txoj kev hnyav kab rov tav CNC tshuab dhos CK61250F series

ck61xxf series yog ib qho kev txhim kho ntawm cov khoom hnyav-txhim kho kab rov tav CNC tshuab dhos nrog plaub txoj kev qhia tsim los ntawm peb lub tuam txhab raws li peb cov kev paub ntev hauv kab rov tav tshuab dhos ntau lawm thiab siv thoob ntiaj teb kev tsim qauv thiab kev tsim tshuab.Nws ua raws li cov txheej txheem tseeb hauv lub tebchaws thiab raug tsim los ntawm kev sib koom ua ke ntawm hluav taws xob, kev tswj tsis siv neeg, hydraulic tswj, kev tsim kho tshuab niaj hnub thiab lwm yam kev qhuab qhia Mechatronic tshuab cuab yeej cov khoom sib koom ua ke ntau pawg ntawm precision manufacturing technology.Cov qauv thiab kev ua haujlwm ntawm lub tshuab cuab yeej siv tau.Lub tshuab cuab yeej muaj cov yam ntxwv ntawm kev ua haujlwm siab thiab zoo li qub, kev ua haujlwm ntev, kev ua haujlwm siab, kev nyab xeeb thiab txhim khu kev qha, kev ua haujlwm yooj yim thiab zoo nkauj tsos.

-

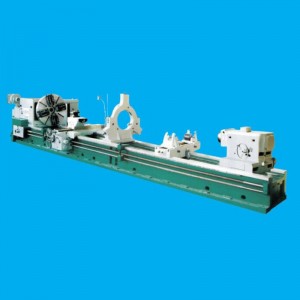

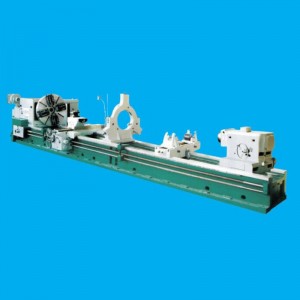

Peb qhia txoj kev hnyav kab rov tav cav tshuab dhos CWZ61160-CWZ61250

Cov cuab yeej siv tshuab no yog lub tshuab ua haujlwm hnyav thoob ntiaj teb nrog peb txoj kev qhia, uas yog tsim rau tig lub voj voog sab nraud, lub ntsej muag kawg, grooving, txiav, tho txawv, tig puab lub khob hliav qab, tig xov thiab lwm yam txheej txheem ntawm ncej, cylindrical thiab phaj ntawm sib txawv cov ntaub ntawv nrog high-speed steel thiab hard alloy steel cov cuab yeej.Thiab tuaj yeem siv lub swb sab sauv (los ntawm kev hloov lub zog) kom tig ntau yam xov nrog qhov ntev luv dua 600mm (ntau-ntev xov tuaj yeem ua tiav rau kev txiav txim tshwj xeeb).

-

Lub rooj zaum kws dhos CZ1340G CZ1440G

* Norton qib gearbox.

* Engineering los ntawm qib siab castings;

* Supersonic zaus hardened txaj txoj kev;

* Precision roller bearing rau spindle;

* High quality steel, av thiab hardened iav hauv headstock;

* Ib qho yooj yim thiab ceev khiav gearbox;

* Muaj zog zog lub cev muaj zog;

* ASA D4 camlock spindle qhov ntswg;

* Metric / Imperial threads txiav ua haujlwm muajTag nrho peb cov khoom yuav tsum tau mus los ntawm peb cais kev kuaj thoob plaws hauv tag nrho cov txheej txheem tsim khoom: hlau casting thiab txhua yam ntawm cov khoom yuav khoom thiab cov khoom ua tus kheej, txhua feem rau lub tshuab sib dhos thiab kev tshuaj xyuas qhov tseeb ntawm cov khoom tiav, Peb tswj cov khoom zoo los ntawm cov khoom siv raw, peb ib txwm xaiv cov ntaub ntawv zoo tshaj plaws, piv txwv li, resin xuab zeb hlau casting nrog HT300 thiab cov khoom siv hluav taws xob nto moo, thiab peb muaj cov neeg soj ntsuam zoo rau txhua tus txheej txheem, qhov zoo yog ib txwm peb muaj kev txhawj xeeb.peb txais tos txhua tus neeg siv khoom los ntawm thoob plaws lub ntiaj teb rau kev koom tes.

-

Lub rooj zaum kws dhos CZ1340G-1 CZ1440G-1

* Ultra audio zaus quenching txaj qhia txoj kev;

* Spindle yog mated nrog precision cov menyuam bearings;

* Cov iav hauv headstock tau hardened thiab hauv av.

* Gearbox yog kev khiav hauj lwm yooj yim.

* Lub cev muaj zog txaus;

* Spindle qhov ntswg yog ASA D4 camlock hom;

* Ntau yam xov txiav ua haujlwm muaj.Tag nrho peb lub rooj zaum lathes yuav tsum tau mus los ntawm peb qhov kev kuaj xyuas thoob plaws hauv tag nrho cov txheej txheem tsim khoom: hlau casting thiab txhua yam ntawm kev yuav khoom thiab tus kheej ua qhov chaw, txhua lub tshuab dhos rau lub tshuab sib dhos thiab kev tshuaj xyuas qhov tseeb ntawm cov khoom tiav, Peb tswj tau zoo los ntawm cov khoom siv raw, peb ib txwm xaiv cov ntaub ntawv zoo tshaj plaws, piv txwv li, resin xuab zeb hlau casting nrog HT300 materal thiab nto moo hom hluav taws xob cov ntsiab lus, thiab peb muaj ib tug zoo soj ntsuam rau txhua tus txheej txheem, zoo yog ib txwm peb sab saum toj kev txhawj xeeb.peb txais tos txhua tus neeg siv khoom los ntawm thoob plaws lub ntiaj teb rau kev koom tes.

-

Lub rooj zaum kws dhos CZ1340A CZ1440A

* Cov khoom siv nres tuaj yeem ua rau spindle nres sai heev, tab sis lub cev muaj zog tsis nres rau kev tiv thaiv zoo dua

* Supersonic zaus hardened txaj txoj kev;

* Precision cov menyuam bearings rau spindle;

* High quality steel, av thiab hardened iav hauv headstock;

* Ib qho yooj yim thiab ceev khiav gearbox;

* Muaj zog zog lub cev muaj zog;

* ASA D4 camlock spindle qhov ntswg;

* Ntau yam threads txiav ua haujlwm muaj -

Kab rov tav cav pa tshuab dhos CW6163E, CW6180E, CW61100E, CE61200E

Lub txaj tshuab dhos yog ntawm ib qho qauv hauv pem teb.Nws yog integrally nrum.Tom qab casting thiab ntxhib machining, nws yuav raug rau kev laus kev kho mob los xyuas kom meej cov txheej txheem rigidity ntawm tag nrho cov tshuab.Txoj kev qhia nto yog nyob rau nruab nrab zaus quenching, hardness tsis tsawg tshaj li HRC52, hardening qhov tob yog tsis tsawg tshaj li 3 hli, thiab stability ntawm tag nrho cov tshuab yog zoo.

Tus qauv tsim tsim ua kom ntseeg tau tias lub tshuab dhos muaj qhov zoo li qub thiab dynamic rigidity txaus.Lub tshuab thev naus laus zis ua kom lub tshuab muaj qhov zoo, tsis tshua muaj suab nrov thiab kev co me me.

Zoo nkauj tsos, ua ke nrog ergonomic cov hauv paus ntsiab lus, yooj yim hloov ntawm workpieces, yooj yim khiav lag luam thiab txij nkawm.

Cov khoom tseem ceeb xws li lub txaj, headstock, carriage thiab tailstock yog ua los ntawm high-zoo resin xuab zeb castings.Tom qab kev laus laus thiab kev laus, cov khoom tseem ceeb ntawm lub tshuab tau lees tias muaj qhov tsis zoo deformation thiab siab stability.

Lub spindle txais peb tus qauv kev txhawb nqa, nrog qhov tsim nyog ncua, tsis tshua muaj suab nrov, tsis tshua muaj cua sov tsim thiab tuav tau zoo.

Lub spindle muaj ntau yam ceev, ruaj khov ua haujlwm, tsis tshua muaj kub nce thiab ruaj khov zoo.

Lub ntsiab kis tau tus mob yog hardened thiab hauv av kom ntseeg tau tias nws cov neeg siab, kev ua haujlwm du thiab tsis tshua muaj suab nrov.

High txiav fais fab thiab kev ua haujlwm siab.

-

Kab rov tav cav tshuab dhos CWA61100-CWA61160

Cov cuab yeej siv tshuab no yog lub tshuab dhos tshuab dav dav, uas yog tsim rau tig lub voj voog sab nraud, lub ntsej muag kawg, grooving, txiav, tho txawv, tig puab lub khob hliav qab, tig xov thiab lwm yam txheej txheem ntawm ncej qhov chaw, cylindrical thiab phaj ntawm cov khoom sib txawv nrog high- ceev steel thiab hard alloy steel cov cuab yeej.Lub spindle txais cov qauv peb-txheej, thiab lub txaj txais ib lub txaj, kom lub txaj muaj kev nruj nruj, thiab lub apron, cuab yeej ncej, thiab lub eeb tuaj yeem txav tau sai.Cov cuab yeej tshuab no muaj qhov zoo ntawm qhov muaj zog rigidity, high efficiency, Safe thiab txhim khu kev qha, yooj yim rau kev khiav lag luam thiab zoo nkauj tsos.

-

Kab rov tav cav pa tshuab dhos CW6163, CW6180(A), CW61100(A), CE61200(A)

Cov cuab yeej siv tshuab no yog lub tshuab tshuab dav dav dav dav, uas yog tsim rau tig lub voj voog sab nraud, lub ntsej muag kawg, grooving, txiav, tho txawv, tig puab lub khob hliav qab, tig xov thiab lwm yam txheej txheem ntawm ncej qhov chaw, cylindrical thiab phaj ntawm cov khoom sib txawv nrog siab. -speed steel thiab hard alloy steel cov cuab yeej.Lub spindle txais cov qauv peb-txheej, thiab lub txaj txais ib lub txaj, kom lub txaj muaj kev nruj nruj, thiab lub apron, cuab yeej ncej, thiab lub eeb tuaj yeem txav tau sai.Cov cuab yeej tshuab no muaj qhov zoo ntawm qhov muaj zog rigidity, high efficiency, Safe thiab txhim khu kev qha, yooj yim rau kev khiav lag luam thiab zoo nkauj tsos.

-

Kab rov tav cav pa tshuab dhos CW61128-CW611208

Qhov no series ntawm cav pa lathes tuaj yeem ua ntau txoj haujlwm tig.Nws tuaj yeem tig lub voj voog sab nrauv, sab hauv lub qhov, lub ntsej muag kawg, metric xov, ntiv tes xov, modulus thiab suab xov thiab lwm yam zoo li tus nto ntawm ntau qhov chaw.Sab saum toj swb tuaj yeem siv los tig luv tapers ntawm nws tus kheej.Sab saum toj swb kuj tseem siv tau los siv lub tshuab ntev tapers thaum nws sib phim nrog cov khoom noj ntev ntawm cov tsheb thauj mus los.Nws tuaj yeem ua tau raws li cov txheej txheem ntawm drilling, tho txawv thiab trepanning.Nws kuj tseem tsim nyog rau kev tig muaj zog nrog cov cuab yeej carbide, Kev ua haujlwm ntawm ntau yam ferrous thiab non-ferrous hlau.

-

Kab rov tav cav pa tshuab dhos CW61126-CW611206

Qhov no series ntawm cav pa lathes tau tsis tu ncua hloov kho thiab txhim kho los ntawm peb lub tuam txhab rau ntau tshaj 40 xyoo, tom qab nqus ntawm advanced tsim thiab manufacturing technologies nyob rau hauv tsev thiab txawv teb chaws, thiab tom qab siv cov neeg siv nyob rau hauv aerospace, railway, valve thiab lwm yam industries, lub kev xyaum tau ua pov thawj tias cov kab rov tav lathes loj uas tsim los ntawm peb lub tuam txhab tau mus txog qib siab hauv Suav teb.

Cov yam ntxwv ntawm no series ntawm lathes yog raws li nram no: thawj, qhov yooj yim qhov chaw, spindle tailstock quill, thiab lwm yam. tau dhau lub optimization tsim thiab zoo ua, nrog high precision thiab lub neej;thib ob, cov khoom tseem ceeb, xws li cov kabmob spindle thiab cov khoom siv hluav taws xob tseem ceeb, yog tag nrho cov npe nrov hauv tsev thiab txawv teb chaws.

-

CNC yeeb nkab threading tshuab dhos, roj teb & hollow spindle tshuab dhos QKD1325-1330-1335 series

Cov cuab yeej siv tshuab no tsuas yog siv rau kev ua cov yeeb nkab xov, thiab tuaj yeem txiav metric thiab nti cylindrical thiab conical yeeb nkab threads.Nws yog tsim rau kev ua tubing, casing, laum yeeb nkab, thiab lwm yam nyob rau hauv roj av, metallurgy, tshuaj, hydropower, geology thiab lwm yam departments.

Mated nrog CNC system, nrog kev tswj siab precision thiab kev ntseeg tau zoo.Lub tshuab cuab yeej tseem tuaj yeem txais PLC maub los, uas txhim kho kev ntseeg tau thiab tswj tau yooj yim ntawm lub tshuab cuab yeej.