Kev qhia

Kev qhia

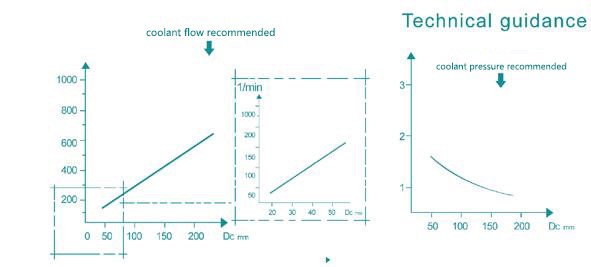

Cov kev txiav tsis yog rau kev siv nkaus xwb thiab kho raws li kev ua haujlwm tiag tiag.Piv nrog cov tshuaj pleev xim sib xyaw, cov roj ntshiab tuaj yeem txhim kho lub neej kev pab cuam ntawm lub cuab yeej.

Teeb meem thiab daws teeb meem

| SN | teeb meem | vim li cas | Kev daws teeb meem |

| 1 | Cov chips hlau tawg me dhau lawm | Tsis ncaj txiav parameter | Kho tej ceev thiab pub |

| Cov nti tawg yog zawj-hom tsis ncaj ncees lawm, thiab lub kaum sab xis elliptical me dhau los yog tob dhau | Hloov cov groove hom tawg nti | ||

| Cov khoom siv ua haujlwm tsis ruaj khov | Kho qhov tsim nyog ceev thiab pub | ||

| Kev txiav pib tsis zoo (workpiece tsis muaj qhov nruab nrab) | Centering lub workpiece | ||

| 2 | Cov chips hlau tawg me dhau lawm | Tsis ncaj txiav parameter | Kho tej ceev thiab pub |

| Cov nti tawg yog zawj-hom tsis ncaj ncees lawm, thiab lub elliptical lub kaum sab xis me dhau los yog ntiav dhau | Hloov cov groove hom tawg nti | ||

| 3 | Cov chips hlau tawg tsis ruaj khov | Cov khoom siv workpiece tsis ruaj khov | Kho txiav ceev thiab pub, hloov qhov zawj hom chips |

| Kev pub mis tsis raug (piv txwv li, hydraulic pub mod) | Tham nrog tus kws tsim tshuab lossis tus kws muag khoom muag | ||

| Tsis txaus cua txias ua rau clogging ntawm nti tawm | Nce coolant | ||

| Muaj zog vibration tshwm sim los ntawm tsis txaus rigidity ntawm workpiece thiab cov cuab yeej | Tham nrog tus kws tsim tshuab lossis tus kws muag khoom muag | ||

| 4 | Fibrous hlau chips | Cov khoom siv workpiece tsis ruaj khov | Kho txiav ceev thiab pub, hloov qhov zawj hom chips |

| Kev pub mis tsis raug (piv txwv li, hydraulic pub mod) | Tham nrog tus kws tsim tshuab lossis tus kws muag khoom muag | ||

| Coolant muaj kab mob | Ntshiab coolant | ||

| Tshuaj affinity tshuaj tiv thaiv ntawm workpiece thiab cemented carbide cuab tam | Tshawb xyuas thiab hloov cov cuab yeej hom | ||

| Txiav ntug chipping | Hloov qhov ntxig lossis lub taub hau drilling | ||

| Pub ceev tsawg dhau | Ua kom nrawm nrawm | ||

| 5 | Cemented carbide tawg ntug | Cov cuab yeej txiav yog blunt heev | Hloov qhov ntxig lossis lub taub hau drilling |

| Tsis txaus coolant | Txheeb xyuas qhov dej txias thiab siab | ||

| Coolant muaj kab mob | Ntshiab coolant | ||

| Qhov kam rau ntawm lub tes tsho qhia me me dhau lawm | Hloov lub tes tsho qhia yog tias xav tau | ||

| Eccentric nruab nrab ntawm drilling pas nrig thiab spindle | Kho qhov eccentric | ||

| Tsis ncaj parameter ntawm insert | Hloov cov parameter ntawm ntxig | ||

| Cov khoom siv ua haujlwm tsis ruaj khov | Kho qhov tsim nyog ceev thiab pub | ||

| 6 | Tool lub neej luv luv | Pub lossis rotating ceev tsis txaus siab | Kho qhov pub thiab rotating ceev |

| Cov qib hard alloy tsis zoo los yog txheej | Xaiv cov qib alloy uas haum raws li cov khoom siv ua haujlwm | ||

| Tsis txaus coolant | Txheeb xyuas qhov ntsuas kub thiab txias txias | ||

| Tsis ncaj ncees lawm coolant | Hloov cov coolant yog tias xav tau | ||

| Eccentric nruab nrab ntawm drilling pas nrig thiab spindle | Kho qhov eccentric | ||

| Tsis ncaj parameter ntawm insert | Hloov cov parameter ntawm ntxig | ||

| Cov khoom siv ua haujlwm tsis ruaj khov | Kho qhov tsim nyog ceev thiab pub | ||

| 7 | Tsis zoo roughness | eccentric | Tshawb xyuas thiab kho |

| Lub nti tawg zawj yog loj dhau los yog qis dua qhov nruab nrab kab | Xaiv qhov tseeb nti tawg zawj | ||

| Tsis yog qhov loj ntawm lub cuab yeej lossis phau ntawv qhia ncoo | Xaiv lub cuab yeej raug | ||

| Eccentric nruab nrab ntawm workpiece thiab drilling taub hau | Kho qhov eccentric | ||

| Muaj zog vibration | Nrog rau lub tshuab tsim los yog kho qhov txiav txiav | ||

| Tsis ncaj parameter ntawm insert | Hloov cov parameter ntawm ntxig | ||

| Txiav ceev yog tsawg dhau | Nce txiav ceev | ||

| Pub ceev yog tsawg heev thaum lub sij hawm machining cov ntaub ntawv nyuaj workpiece | Ua kom nrawm nrawm | ||

| Pub tsis ruaj khov | Txhim kho cov qauv pub | ||

| 8 | Eccentric | Qhov sib txawv ntawm lub workpiece los ntawm qhov chaw machining ntawm lub tshuab yog loj heev | Kho dua |

| Drilling pas nrig ntev dhau lawm, linearity tsis zoo | Kho dua | ||

| Hnav cov ntaub qhwv thiab cov ntaub ntawv qhia | Hloov cov ntxig lossis lwm qhov chaw | ||

| Yog vim li cas rau cov khoom siv ua haujlwm (tus yam ntxwv, hardness thiab impurity thiab lwm yam) | Xaiv cov cuab yeej tsim nyog thiab txiav qhov ntsuas | ||

| 9 | Ntsia hlau qhov | Sab nrauv sab nraud yog tawg | Hloov qhov ntxig |

| Daim ntawv qhia ncoo hnav los yog kev txhawb nqa tsis txaus | Hloov lossis kho | ||

| Ntau tshaj centering eccentricity ntawm lub tshuab thiab workpiece | Kho dua | ||

| Coolant thiab lubrication tsis txaus | Kho coolant thiab coolant qauv | ||

| Txiav ntug yog blunt heev | Hloov qhov ntxig | ||

| Tsis ncaj txiav parameter | Kho qhov ntsuas | ||

| Rigidity thiab pub zog tsis txaus | Kho tshuab lossis txo qhov drilling txoj kab uas hla | ||

| 10 | Kev vibration loj dhau thaum ua haujlwm | Txiav ntug yog blunt heev | Hloov qhov ntxig |

| Tsis ncaj txiav parameter | Kho qhov ntsuas | ||

| Rigidity ntawm lub tshuab los yog pub zog tsis txaus | Kho tshuab lossis txo qhov drilling txoj kab uas hla |