tho txawv lub taub hau, tho txawv thiab dov ua ke cov cuab yeej

TJ hom roller-adjustable ntxhib

Muab piv rau cov pa tho txawv lub taub hau, hom tshiab muaj qhov zoo hauv qab no:

Kev taw qhia los ntawm cov menyuam, nrog kev txhawb nqa ntau lub ntsiab lus thiab cov lus qhia ruaj khov.

Qhov taw tes sib cuag ntawm cov menyuam thiab cov phab ntsa sab hauv ntawm lub workpiece txo qhov kev sib txhuam thiab ua kom lub neej ntev;Qhov tseem ceeb tshaj, nws zam qhov teeb meem ntawm kev hloov cov ntaub ntawv qhia ntau zaus.

Cov khoom tsim tau tuaj yeem nce ob npaug.

Qhov loj tuaj yeem hloov kho hauv thaj tsam ntawm 5 hli, nws tsis tas yuav hloov qhov chaw, yog li kev ua haujlwm yooj yim heev thiab txuag sijhawm.

Cov menyuam siv lub teb chaws tus qauv, nws yooj yim heev kom tau txais ntawm tus nqi tsim nyog hauv kev ua lag luam, kev siv const yog tsawg.

Hom tshiab tho txawv lub taub hau yog sim dua, nws muaj qhov kev ua haujlwm ruaj khov thiab tau txais lub koob npe zoo los ntawm tus neeg siv.

T hom adjustable tho txawv taub hau

Lub taub hau tho txawv no siv cov kabmob sab hauv ob sab, cov ntawv qhia ncoo tsis tig nrog lub cuab yeej.Nws muaj qhov hnav tsawg tshaj plaws thiab cov cuab yeej tig tau yooj yim.Qhov kev hloov loj tuaj yeem ua tiav los ntawm kev hloov cov ntawv qhia kab txaij lossis nce & txo cov shim.Qhov loj ntawm daim cartridge tuaj yeem hloov kho hauv qee qhov ntau.Nws yooj yim heev thiab txhim khu kev qha.

TGG/TTG boring

Cov cuab yeej ua ke no yog qhov ua tau zoo tho txawv thiab cov menyuam kub hnyiab taub hau.Integrated nrog ntxhib boring, nplua boring thiab cov menyuam burnishing, lub cuab tam yog txuas nrog tho txawv pas nrig los ntawm cov duab plaub.Nws muaj cov khoom tsim tau zoo rau kev ua haujlwm nrog cov phab ntsa tsis sib xws hauv lub koomhaum loj.

| Spec.ntawm boring taub hau | Ntxoov pas nrig | Spec.ntawm boring taub hau | Ntxoov pas nrig | Spec.ntawm boring taub hau | Ntxoov pas nrig |

| Ib 60-72 | Φ56 | Ib 73-77 | Φ65 | Ib 78-87 | Φ70 |

| Ib 88-107 | Φ80 | Ib 107-137 | Φ100 | Ib 138-177 | Φ130 |

| Ib 178-250 | Φ160 | Φ250-500 | Φ220 |

TJ type mechanical

Cov cuab yeej no txais yuav ib leeg-edged indexable configuration, haum rau ntxhib thiab semi-zoo tho txawv ntawm qhov tob.

| Spec.ntawm boring taub hau | Ntxoov pas nrig | Spec.ntawm boring taub hau | Ntxoov pas nrig |

| Φ32 | Φ27 | Ib 88-107 | Φ80 |

| Φ35 | Φ30 | Ib 108-137 | Φ100 |

| Φ50-60 | Φ43 | Ib 138-177 | Φ100 |

| Ib 61-72 | Φ56 | Ib 178-300 | Φ160 |

| Ib 73-77 | Φ65 | Φ300-500 | Φ220 |

| Ib 78-87 | Φ70 |

JT hom tshwj xeeb cartridge

Lub cartridge txais cov cuab yeej clamping indexable ntxig nrog txheej txheej, qhov ntev yog micro-adjustable.Kev sib txuas ntab yog siv ntawm cov cartridge thiab lub taub hau tho txawv.Nws yog qhov tsim nyog rau kev ua tiav ntawm qhov tob tob.

| Cutter loj | Mated tho txawv taub hau | Cutter loj | Mated tho txawv taub hau |

| 12 x 25 | 40- <60 | 20 x 25 | ≥90-<140 |

| 16 x30 | ≥60- <75 | 25 x50 | ≥140- <200 |

| 16 x40 | ≥75-<90 |

|

|

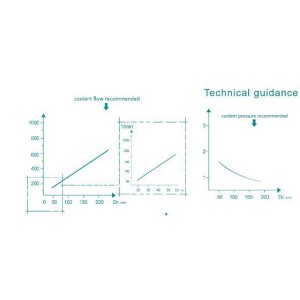

GY hom sib sib zog nqus qhov dov

Lub taub hau dov no yog siv ntawm qhov kub thiab txias nrog ntau lub cylindrical rollers.Nws tuaj yeem tsim cov yas deformation ntawm cov hlau nto thiab txhim kho micro roughness.Yog li, nws yuav siv qhov chaw ntawm qhov chaw kho cua sov thiab cov txheej txheem machining zoo.Cov cuab yeej no tuaj yeem hloov kho micro thiab siv tau zoo heev thiab txhim khu kev qha.

| Spec.ntawm dov taub hau | Ntxoov pas nrig | Spec.ntawm dov taub hau | Ntxoov pas nrig |

| Ib 38-43 | Φ35 | Ib 88-107 | Φ80 |

| Ib 44-48 | Φ40 | Ib 107-137 | Φ100 |

| Ib 49-60 | Φ43 | Ib 138-177 | Φ130 |

| Ib 61-72 | Φ56 | Ib 178-250 | Φ160 |

| Ib 73-77 | Φ65 | Φ250-500 | Φ220 |

| Ib 78-87 | Φ70 | Φ500-800 | Φ350 |

JT hom tob qhov zoo tho txawv

Cov cuab yeej no siv ob-edged floating configuration, haum rau nplua boring ntawm qhov tob.

| Spec.ntawm boring taub hau | Ntxoov pas nrig | Spec.ntawm boring taub hau | Ntxoov pas nrig |

| Φ40-42 | Φ35 | Φ90, 95, 100, 105 | Φ80 |

| Φ45 | Φ40 | Φ110, 115, 120, 125, 130, 135 | Φ100 |

| Φ50, 55, 60 | Φ43 | Φ140, 150, 160, 170 | Φ130 |

| Ib., 63, 65, 70 | Φ56 | Φ180, 190, 200 | Φ160 |

| Φ75 ua | Φ65 | ≥ Φ200-300 | Φ160 |

| ib 80,85 | Φ70 | ≥Φ300-500 | Φ220 |

Nruab nrog inserts ntawm lub ntiaj teb nto moo hom xws li Sandvik, Iscar thiab Taegutec uas tuaj yeem kho raws li kev xav tau sib txawv ntawm cov neeg siv.